SHRI VENKATESHWARA HI-TECH INDUSTRIES

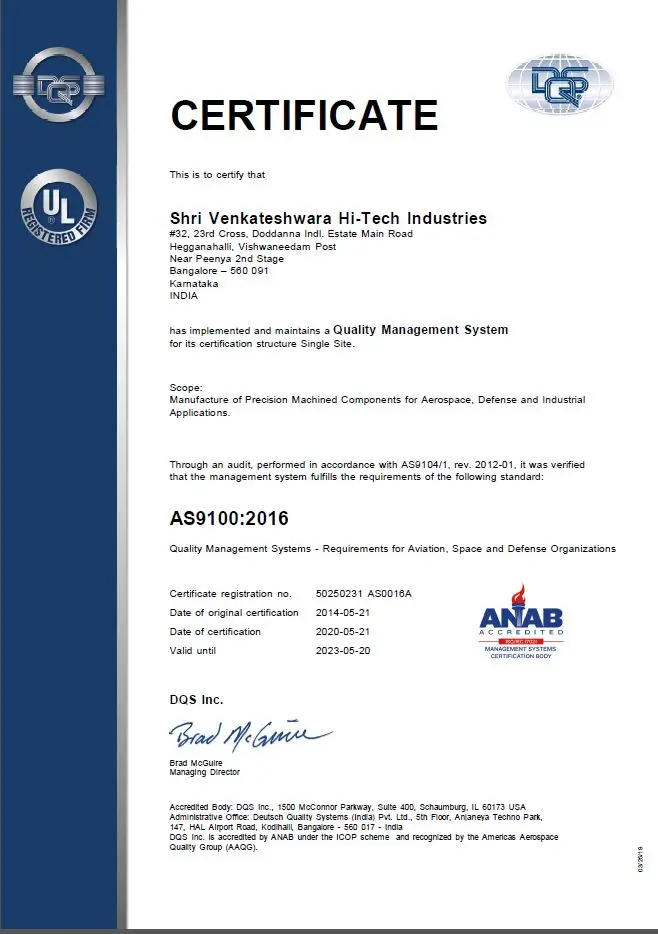

( AS9100 : 2016 & ISO 9001 : 2015 Certified Company )

Manufacturers & Exporters of Precision CNC Machined & Turned Components

Aircraft Components

Aero Engine Components

Helicopter Components

Aerospace Components

Shri Venkateshwara Hi-Tech Industries was established in the year 2006, as one of the most sophisticated manufacturers and supplier Aerospace parts and engine components manufacturing companies based out of Bangalore, India.We are among the well known manufactures and suppliers of Aerospace engine components and spare parts for Aircraft, Aeroplane, Helicopter and Jet engines. Our exclusive Computer Numerical Control (CNC) unit with CNC Vertical Machining center works under a well-defined coordination and able leadership of self-motivated and well-qualified engineers and enthusiastic, dedicated, and experienced technical personnel. We provide a huge array of Precision CNC 2D, 3D & Complex Milling components, Aero engine, Aircraft & Aerospace Components & also Dies, Moulds, Electrodes, Jigs & Fixtures & all type Of Engineering materials to our clientele. Composite CAD/CAM soft wares are used for high quality and high precision results. We use high tech technology and latest machinery and equipments in our productions and ensure constant up gradation to ensure and maintain highest quality standards. We are a company involved in manufacturing important parts and are engaged in making sub assemblies for passenger aircrafts, helicopters, light combat aircrafts, jet trainers, fighter planes and advance jet trainers

We have a full-fledged CAD CAM facility along with first-rate CNC machining technologies. We vision to grow at a very fast and become a prominent supplier.

Shri Venkateshwara Hi-Tech Industries is a joint venture with Mr. Narayana Reddy V. & Mr. Manjunatha Gowda B. as mutual partners. Both have spent valuable years in the hi-tech machine and aerospace industry and acquired expertise in this field. The collaborative initiative between the two has laid the foundations of a flagship company that has already established itself as a premier organization known for its quality products in a short span of time.

We have attained the proficiency with our expertise in the manufacturing of complex components to exacting tolerances in a wide range of metals for the local and international aerospace industry. With utmost utilization of CNC technology, we encompass the design and production of small to large, small batch to high volume and simple to complex components. Our products qualify the entire standard manufacturing tests and maintain the highest quality levels.

We believe in serving you in the best way assure you the best service and support at all times. We look forward for an opportunity to serve you and anticipate for your valuable orders.

We are fully committed and dedicated towards an enduring customer and client satisfaction. In our company constitution, we are faithful to meet the expectations and needs of our clientele. We look forward to provide superior quality products and excellent services. And for that, we conform to the product manufacturing standards and qualify the stringent norms of measurable quality production set by the government of India.

Our quality management system works rigorously for an effective implementation. We pursue the most efficient testing and control measures under a strict supervision and administration. There is a continuous yearning to follow our guidelines for a better management leading to better production. We strive for customer satisfaction in the best possible way and constantly work to enhance our standards.

In order to cater to the requirements and demands of our customers, we have planned to extend our product series in various categories. We intend to expand our product catalogue in the CNC category, viz., CNC Vertical Machine Center (High Speed M65, 2 nos.) with Transverse: X 1270mm, Y 635mm, Z 635mm & CNC Turning Center (High Speed, 2 nos.) with Transverse: 750 DIA/ 1000 lengths specifications.

Manufacturing of these products is scheduled in the closest time possible.

Shri Venkateshwara Hi-Tech Industries

AS 9100:2016 & ISO 9001:2015 Certified Company

No. 32, 20th Cross, Doddnna Industrial Estate Main Road, Hegganahalli, Vishwaneedam Post, Near Peenya II Stage, Bangalore-560091, Karnataka, India.

Call Us: +919449632621, +919449544649

Email: info@svhitechind.com

Location

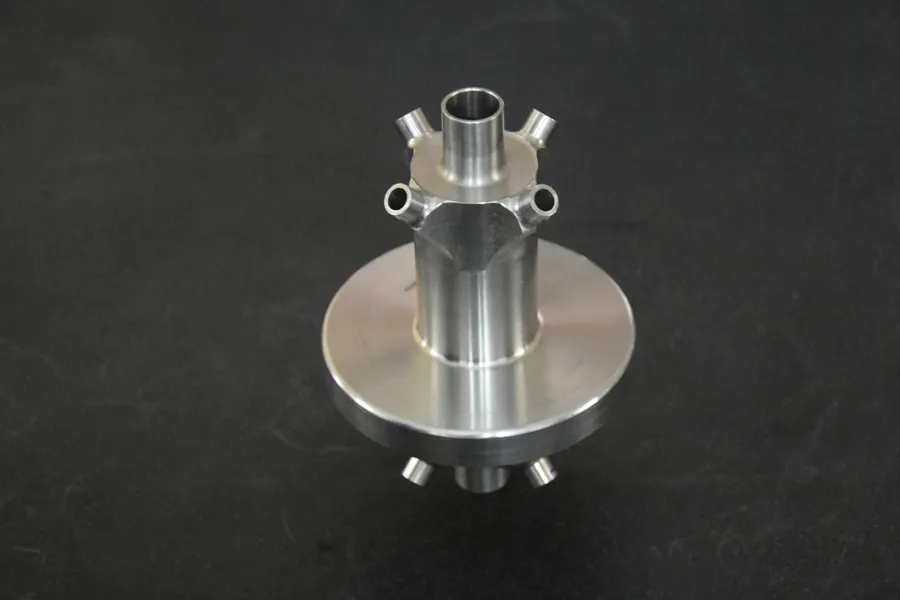

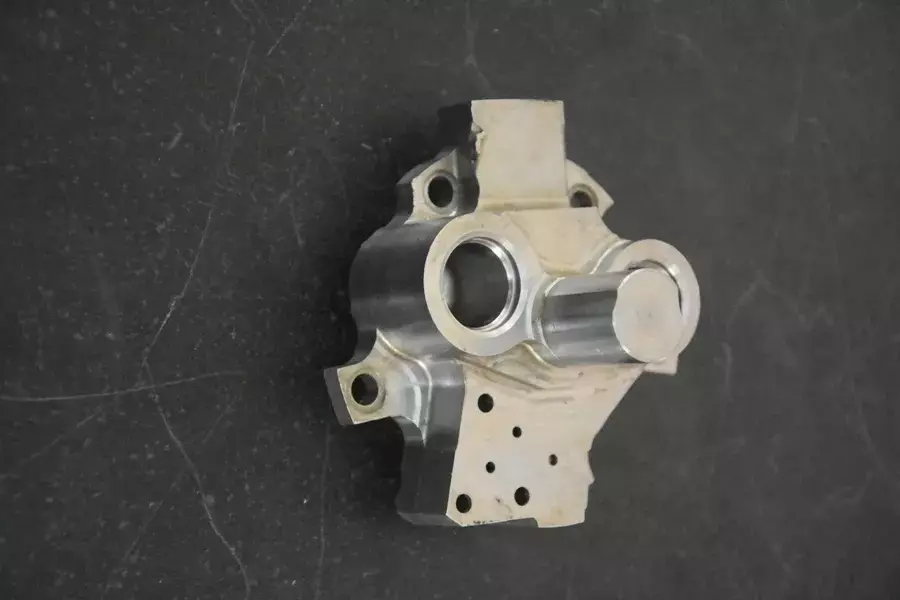

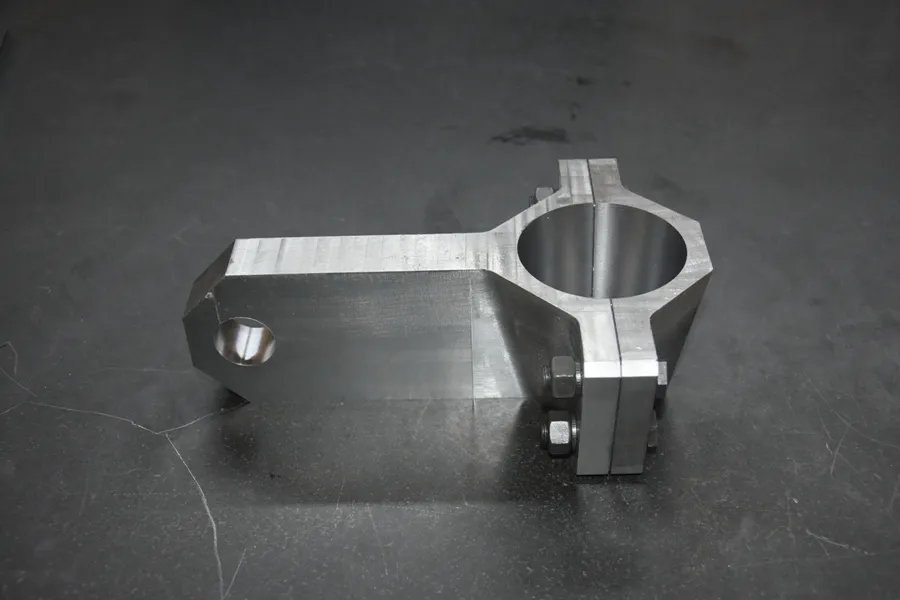

We manufacture and supply aerospace components, spares, hardware, seals, and various ground support items. Our customers are benefited of working with an organization that provides customized and integrated solutions in support of the delivery of their business requirements. Our aero engine parts are machined from stainless steel, NCM steel, titanium, nimonic, inconel alloys.

All components are manufactured using the cutting edge technology and skilled workforce manufactures export quality components.

Aerospace & Aircraft Components

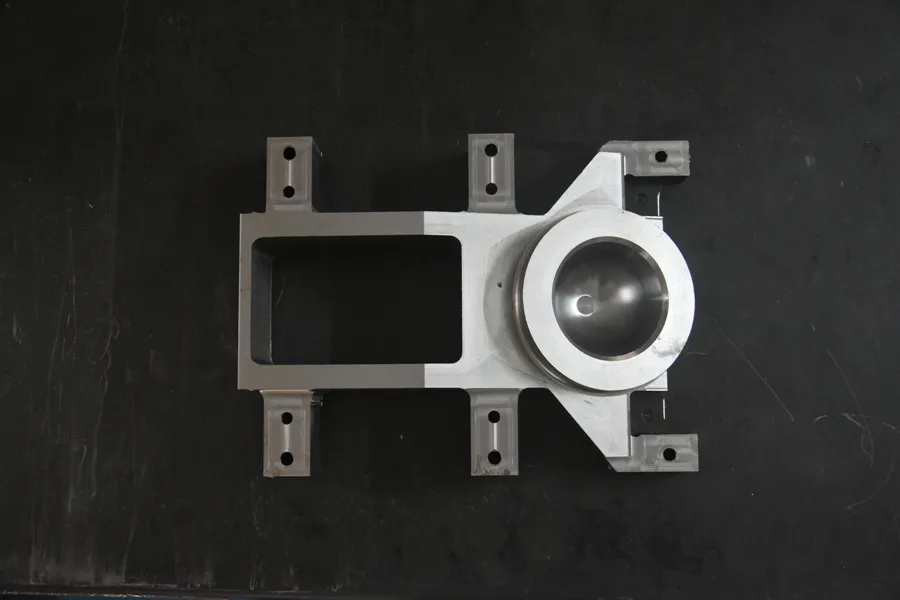

The standards of equipment & machinery quality, product performance and safety in the commercial, space and military sectors of the aerospace industry are very strict. We manufacture parts like Aircraft Structure and sub assemblies for various aircrafts. We follow the guidelines and standards for quality production. Based on product category, bifurcations have been done as under:

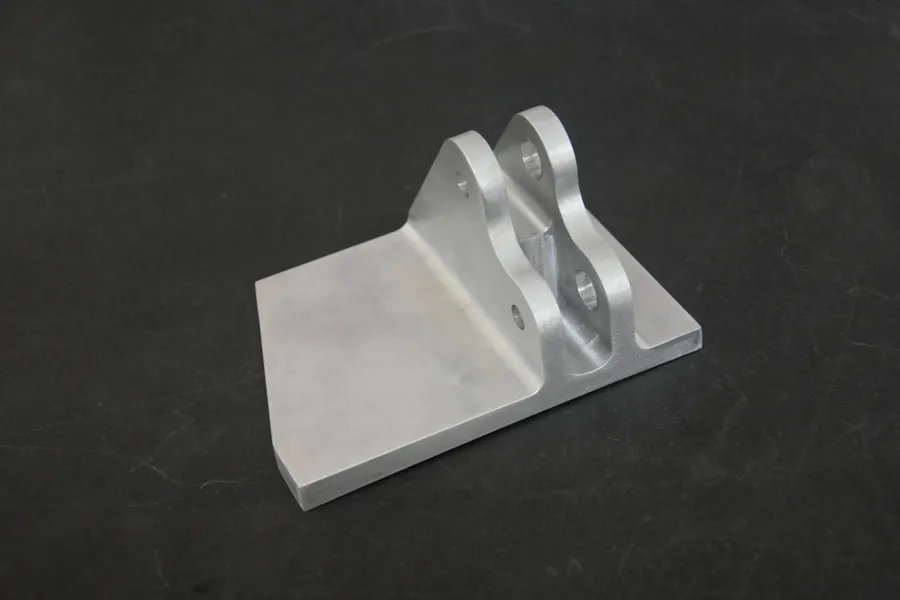

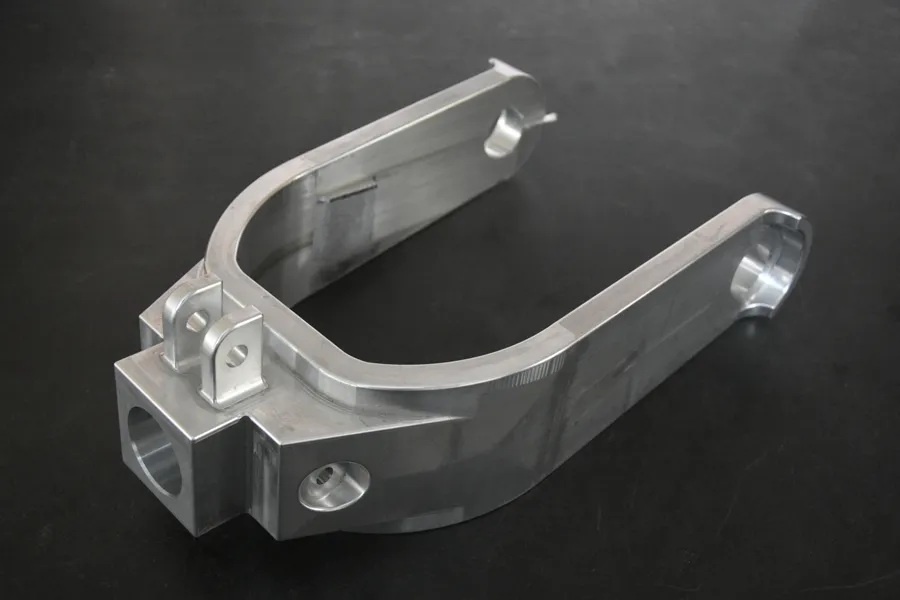

Aircraft Structure

Modern aircraft structures are made using a contemporary concept- a basic load-carrying shield reinforced by frames and parts in the bodies. Spars and ribs in the surface support the skin-stringer edifice. With fail-safe design concepts, we manufacture aircraft structures keeping in mind greater strength. Aluminum alloy is known for its special properties of high sustenance and durability. We manufacture Aircraft and aerospace structural items machined from aluminums alloy billets. Reputed aircraft companies are a part of our client list.

Computer Numerical Control (CNC) refers to a computer controller that runs a powered mechanical device used to fabricate metal components by careful metal removal. Increased automation of manufacturing processes with CNC machining technology has brought about considerable improvements in the quality and consistency of the manufactured items. CNC reduces the scope and is less time consuming. We manufacture CNC Precision turned components used for machineries spares and aero engine components.

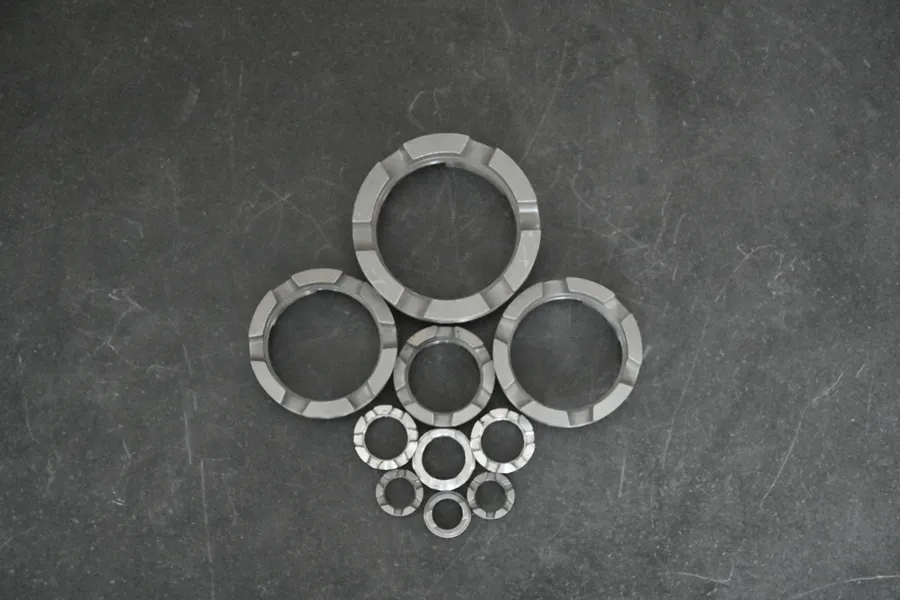

Sealing Glands And Rings

Sealing glands or sealing transits and sealing rings are used to safeguard instrumentation wire and tubing, of various machinery. A variety of metals are used in their manufacturing. Sealing glands and rings are manufactured from a number of materials, all of which lend different characteristics to the quality of the gland. We manufacture sealing glands in stainless steel varieties. With superior service strength, stainless steel provides an elevated level of corrosion resistance. We manufacture mechanical seals and rings, mechanical packing and sealing support systems that are complemented by power transmission couplings. Used in centralized lubrication systems.